Pharmaceutical & Healthcare

Safeguard Your

Temperature-Sensitive

Pharmaceutical Products

MONITORING

Guaranteeing the quality and integrity of your temperature-sensitive items

For pharmaceutical shipments, ensuring their quality requires monitoring of location and temperature during transit. Tempmate provides a solution that offers verified visibility into these critical shipments. This empowers you to curtail excursions and uphold product excellence from start to finish.

MONITORING

Tempmate offers diverse monitoring solutions

to ensure optimal transportation conditions

- Ensure Quality and Traceability by supervizing a wide range of temperatures: dry ice (-78.5°C), frozen (-25°C to -15°C), refrigerated (+2°C to +8°C) or controlled room temperature (+15°C to +25°C)

- Prevent Loss with alarms based on configurable thresholds

- Optimize on-time deliveries thanks to localisation

Demonstrating Regulatory Compliance

Staying in line with standards and regulations is crucial for both assuring product quality and avoiding legal repercussions.

- Good Distribution Practices (GDP) compliance

- Temperature recorders in accordance with EN12830 standard

- Every data logger includes an individual 6-point temperature validation certificate

- Software with audit trail and CFR21 Part 11 compatibility

PRODUCTS

A solution for every need

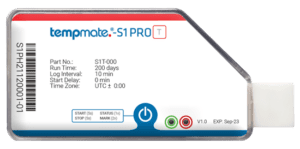

tempmate.®-S1 PRO:

USB temperature data logger

Ensure the integrity of your supply chain with the tempmate.®-S1 PRO, a reliable and user-friendly USB temperature data logger that safeguards your temperature-sensitive products.

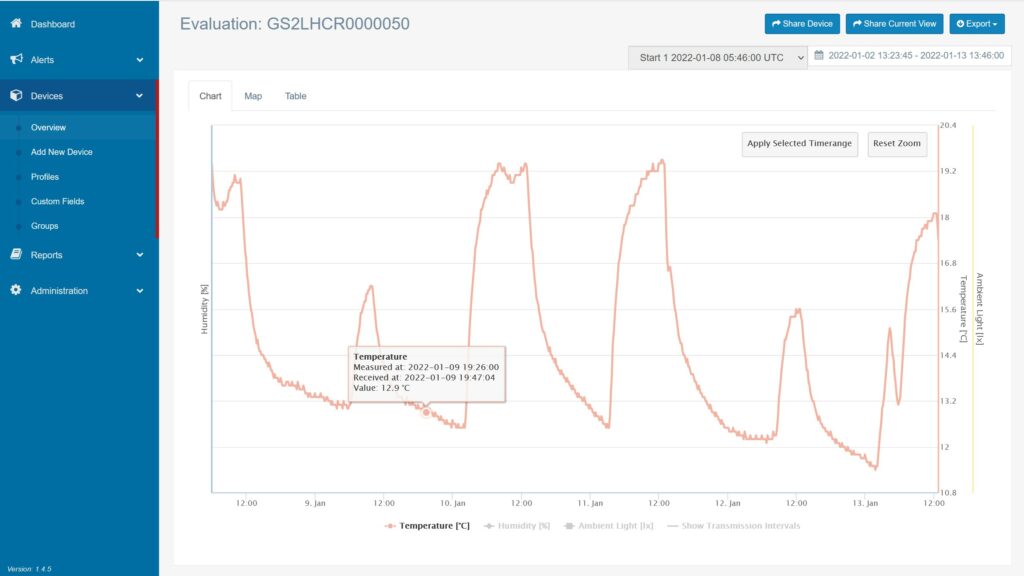

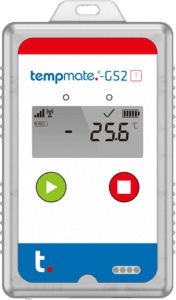

tempmate.®-GS2:

4G Real-time temperature data logger

Daniel Fiedrich

Product Specialist

We’d love to hear from you.

You are currently viewing a placeholder content from reCAPTCHA. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information